GSK 25i CNC Milling System

- Product Details

- Company Profile

1. GSK25i is a high-performance CNC system characterized by its powerful functions and simple operation. It is applicable to the multi-function machining centers, boring machines, milling machines and drilling machines with 3~5 axis linkage. 2. GSK25i adopts a high-performance hardware platform and Linux operation system. It supports up to 8 axes with 5-axis linkage, and provides five-axis control functions, such as five-axis RTCP (tool center point control), inclined plane (3+2 positioning) machining and five-axis manual feeding. In addition, it supports the feed axis synchronization and PLC axis control as well.

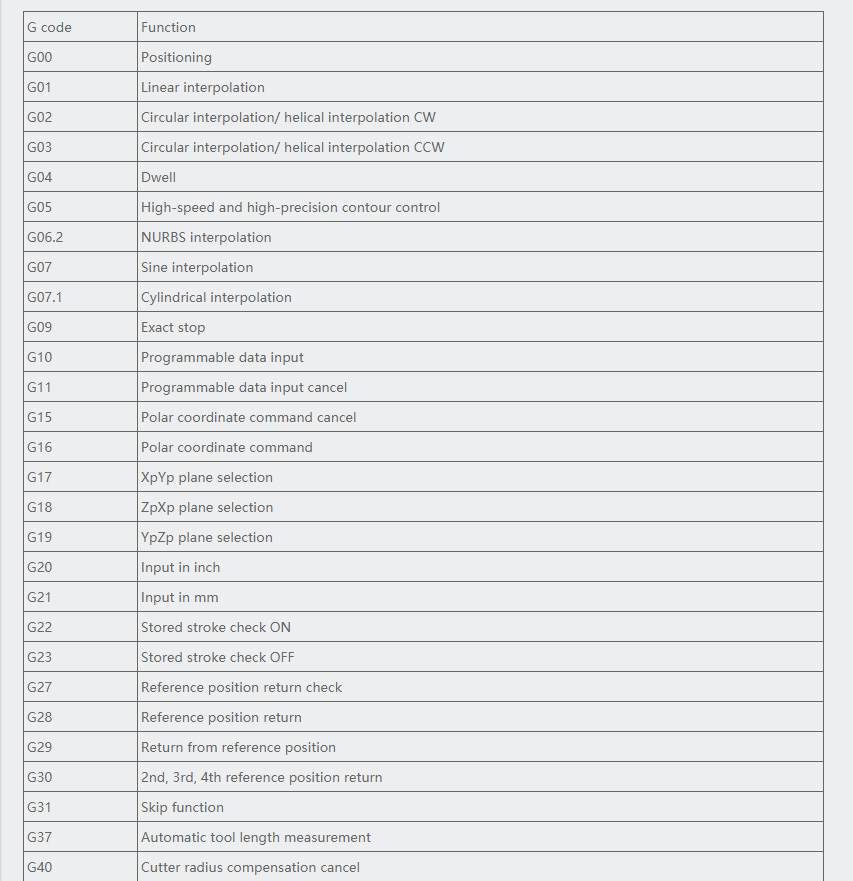

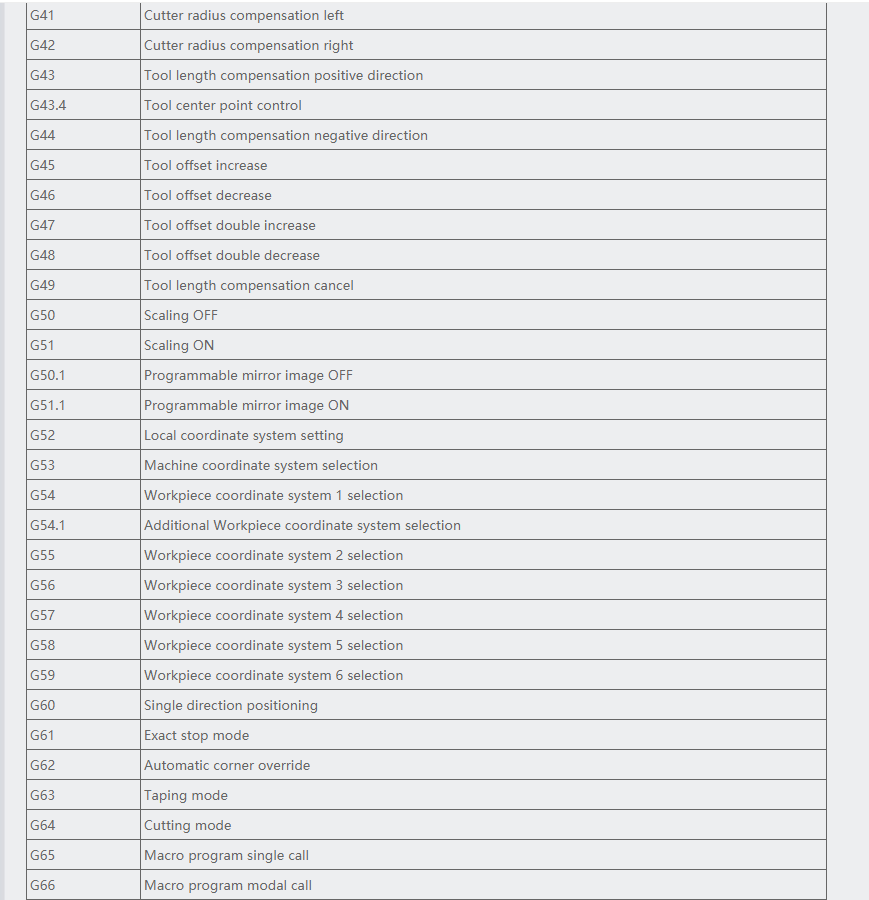

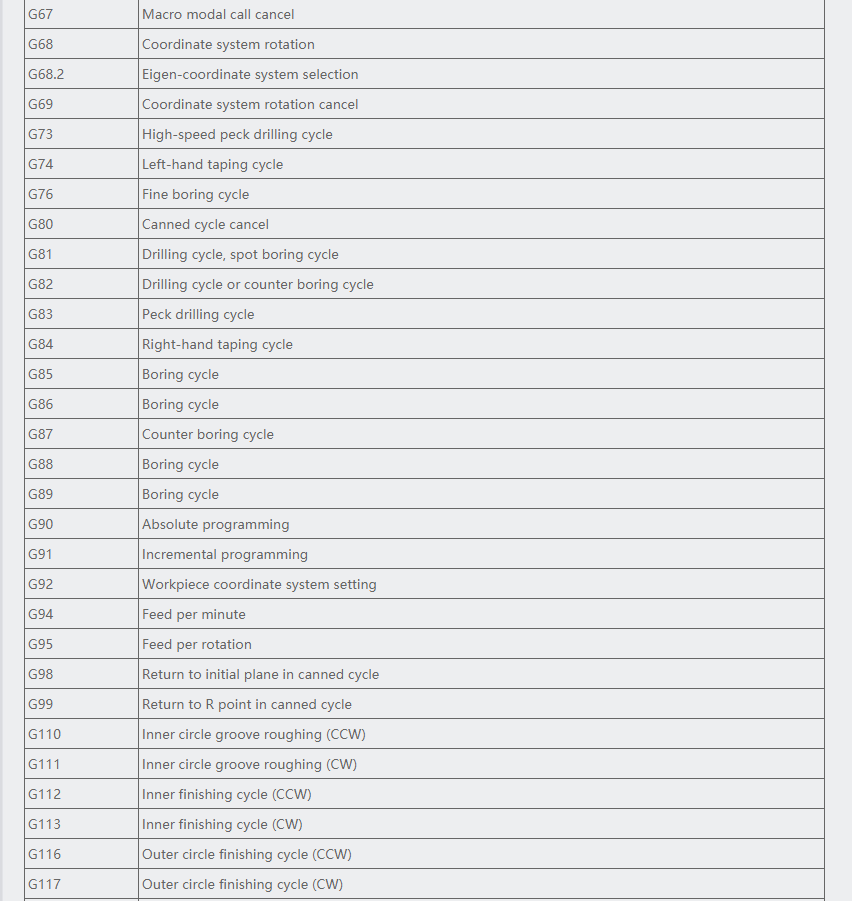

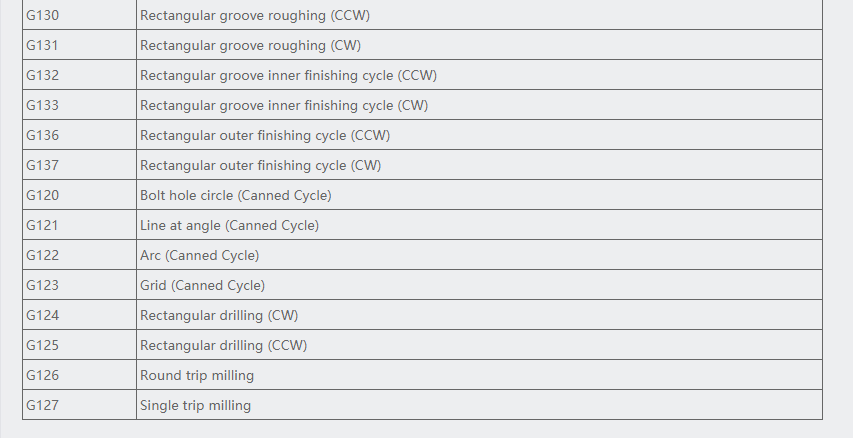

InstructionList:

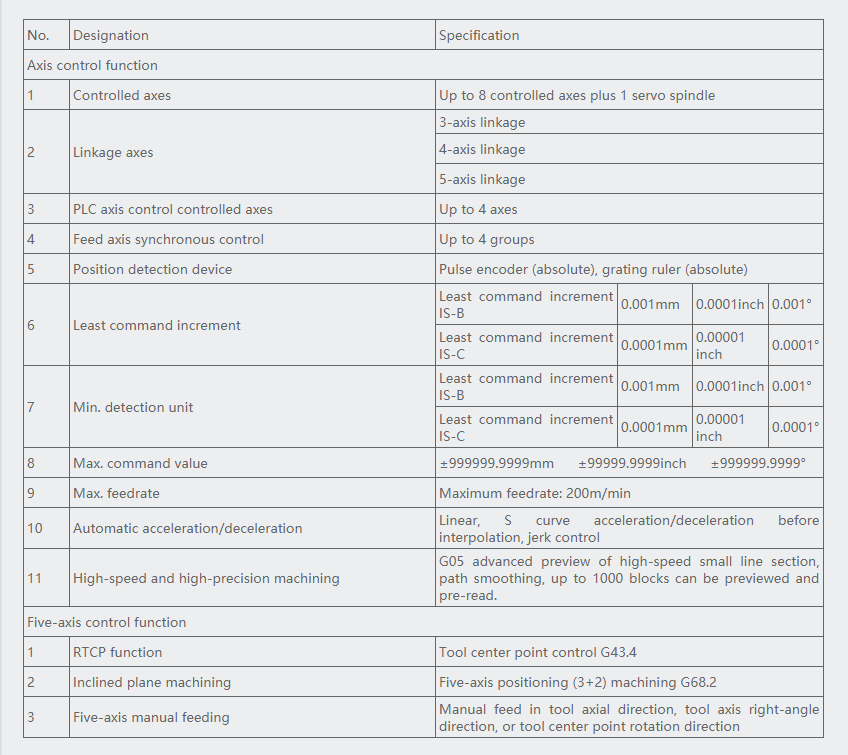

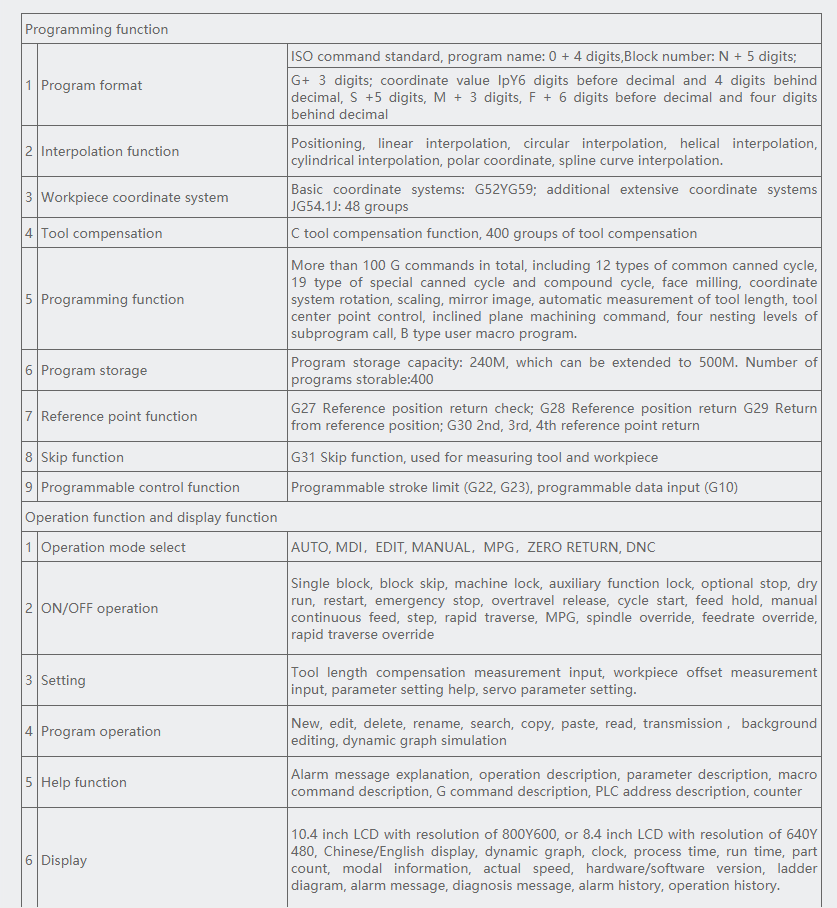

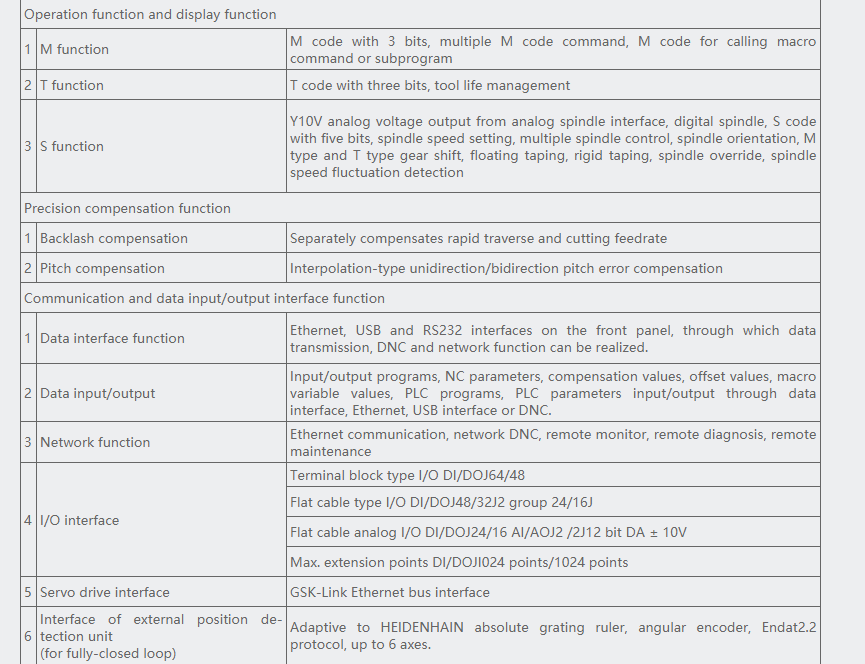

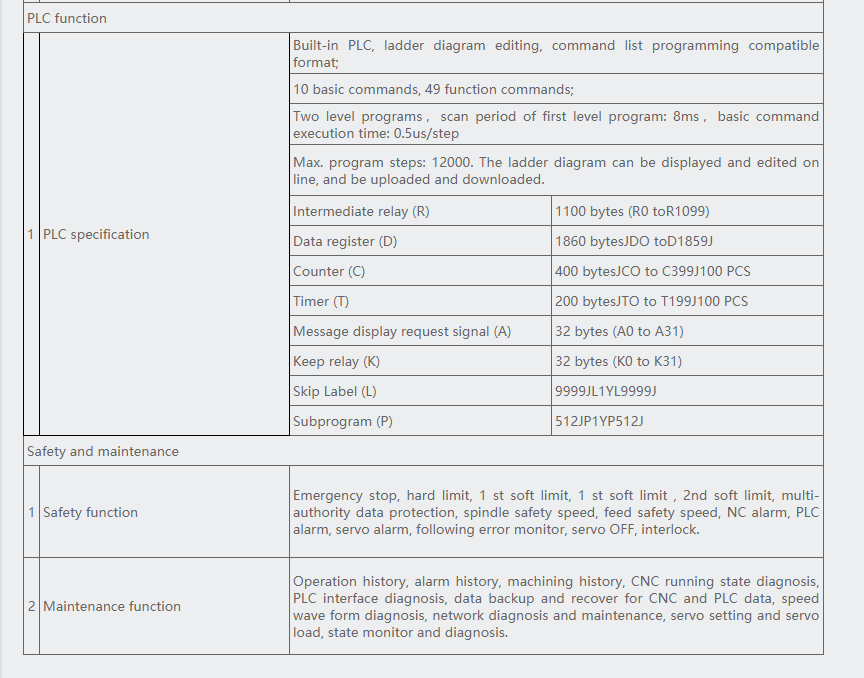

FunctionParameters:

Advanced hardware

1.High-performance and high-configuration hardware platform, which satisfies the demands for complicated operation and machining, such as five-axis linkage and high-speed and high-precision machining.

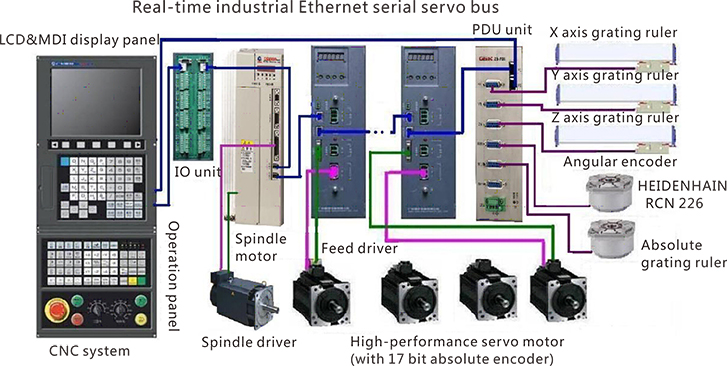

2.GSK-Link real-time industrial Ethernet bus control, integrated cabinet, high-resolution LCD, small size and simple connection.

3.Aluminum alloy front panel, stainless steel rear panel, firm and durable.

Five-axis machining function 8 controlled axes with 6-axis linkage

1.8 controlled axes with 6-axis linkage

2.Applicable to five-axis machines with worktable swinging, tool swinging or both.

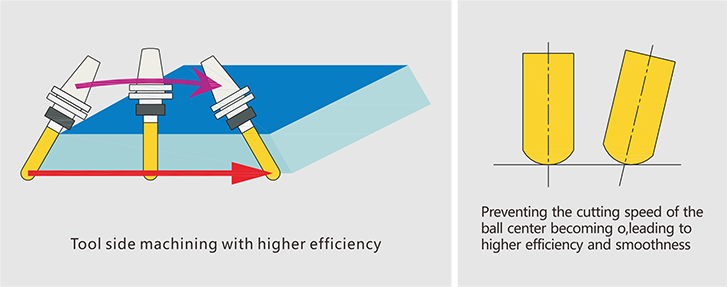

3.Five-axis RTCP (tool center point control)

4.Inclined plane machining (3+2) positioning

5.Five-axis manual feed

High-speed and high-precision machining

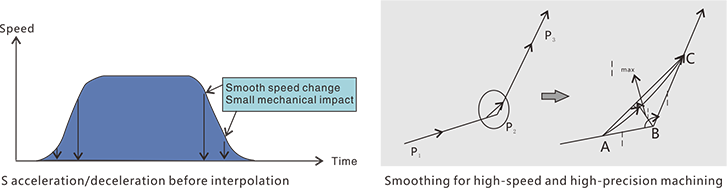

Advanced preview control (up to 1000 blocks), linear acceleration/deceleration before interpolation, S acceleration/deceleration before interpolation

2.Jerk control

3.NUBRS interpolation

4.Multiple on-line path smoothing modes, coordinating the work efficiency and surface quality in different types of machining.

5.G05 P1 Broken line transition mode

6.G05 P2 Bezier smoothing mode

7.G05 P3 B spline smoothing mode

High-performance servo system

1.High dynamic response servo motor, current loop cycle as short as 100|s

2.Servo parameter dynamic self-adjustment

3.Servo motor equipped with a 17-bit (131072 lines) high-resolution absolute encoder, which improves the machining precision and surface quality to a new level.

4.Absolute encoder. No need to return to the zero point each time the system is started up.

5.Large-capacity memory, 240M standard configuration, which can be extended to 500M.

6.Operations for program editing: New, Modify, Copy, Cut, Paste, Search, Replace.

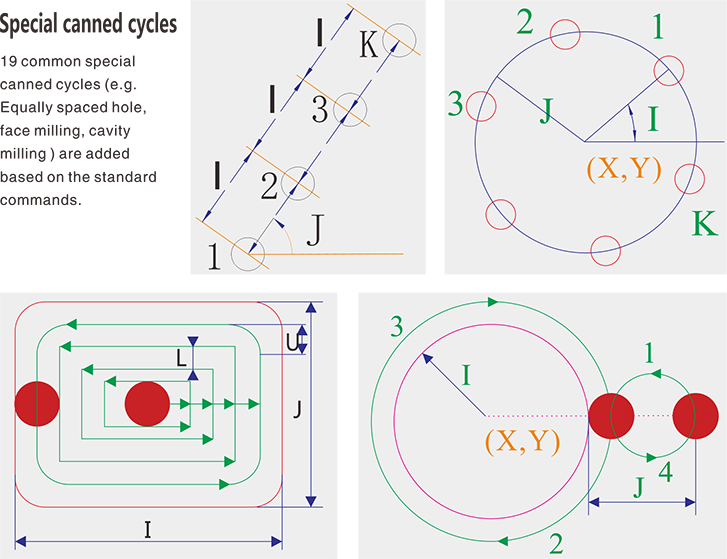

7.Plenty of macro commands and canned cycles, convenient for effectively completing complicated machining.

8.Data transmission through U disc and network, DNC.

9.Simple debugging and maintenance, detailed alarm and diagnosis message.

10.Multi-level authority management.

11.User-defined interfaces for secondary development.

.png)

.png)

PLC function

1.Ladder diagram programming.

2.Basic command process time: 0.5|s/step, program capacity: 12000 steps.

3.10 basic commands, 49 function commands.

4.Open PLC, PLC program can be modified and edited on the system.

5.Multiple PLC program select storage, run program selectable.

6.PLC axis control function.

ConfigSoftware:

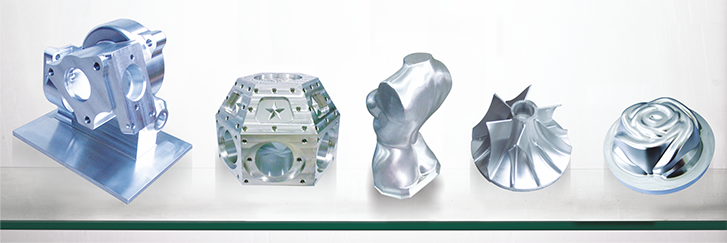

Applycase:

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier