Panel Production Line Stone Coated Roof Tile Production Line

- Product Details

- Company Profile

Colorful?stone coated?metal?roof?tile?is?a?modern?environmentally?friendly?roofing?material?with?the?basic?of?0.4mm?Al-zin?coated?steel.Covering?color?vermiculite?surface?which?carried?under?the?high?temperature?technology.It?is?high-performance, stable,?energy-efficient?and?easy?operation.

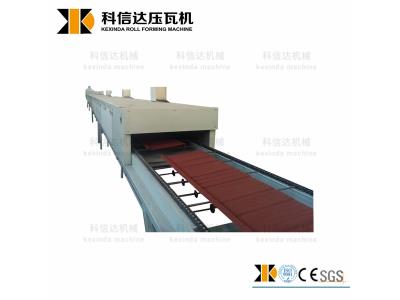

panel produciton line stone coated roof tile production line

Special offer!!! HOT!!! BEST SALES!!!

This production line is very popular now.

Colorful stone coated metal roof tile is a modern environmentally friendly roofing material with

the basic of 0.4mm Al-zin coated steel.

Covering color vermiculite surface which carried under the high temperature technology.

It is high-performance, stable, energy-efficient and easy operation.

Product Description

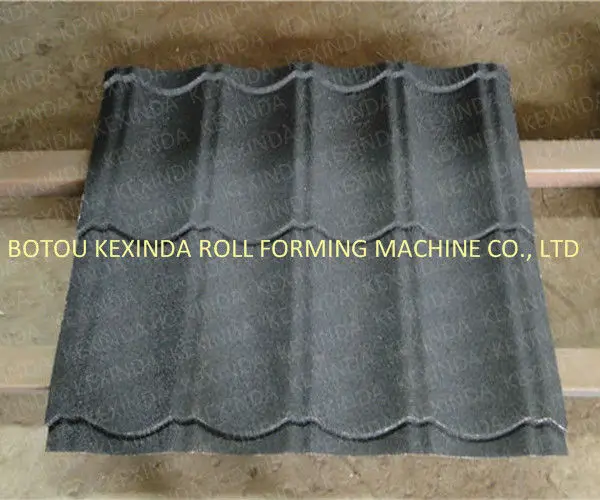

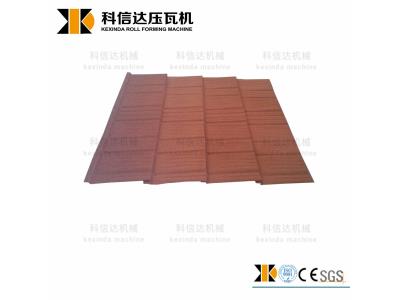

Sample roof panel:

_____________________________________________________________________

Step 1: The roofing tile profile forming

Slitting the sheet — Lace shearing — Press the profile

Slitting:

Lace shearing:

Pressing the profile: (can change the mould)

Step 2: Sand blasting (the stone coated)

It is including five main parts:

1 Auto bottom glue spraying section

2 Auto stone coated section

3 The first time drying section

4 Auto face glue spraying section

5 The second time drying section

Detail Introduction:

NO. 1 Auto bottom glue spraying section | |

Appearance size | 4000*1000*2000mm |

Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements ) |

Automatic pressure spray tank | 1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

Automatic glue machine motor | Servo motor ; Power: 750w ; PLC |

Automatic spray gun | 4 set (spare parts) |

Dust collecting fan | 1 set ; Power: 200w |

Damp proof lamp | 1 pc ; Power: 100w |

Conveying device | Chain reciprocating |

Air compressor | 1 set ; Power: 7.5kw |

Dust control of axial flow fan | 1 set ; Power: 200w |

Agitator | 1 set ; Power: 1.5kw |

NO. 2 Auto stone coated section | |

Appearance size | 3500*1000*1500mm |

Framework | Steel welding |

Conveying device | Chain reciprocating |

Automatic sand hopper | 1 set ; Capability: 200kg |

Bucket lift | 1 set |

Manual sandblast gun | 4 sets |

NO. 3 The first time drying section | |

Appearance size | 25000*1000*1200mm |

Framework | Steel welding |

Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

Automatic temperature controller | 4 sets ; Range: 0°~160° |

Infrared heating tube | 30pcs ; Power: 30kw |

Conveying device | Chain reciprocating |

Air cooling device | 1 set ; Power: 200w |

NO. 4 Auto face glue spraying section | |

Appearance size | 3000*1000*2000mm |

Framework | Steel welding |

Damp proof lamp | 1 pc ; Power:100w |

Automatic pressure spray tank | 1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

Conveying device | Chain reciprocating |

Automatic spray gun | 4 sets (spare parts) |

Manual patch glue gun | 4 sets |

Dust control of axial flow fan | 1 set ; Power: 200w |

Automatic glue machine motor | Servo motor ; Power: 750w |

NO. 5 The second time drying section | |

Appearance size | 30000*1000*1200mm |

Framework | Steel welding |

Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

Automatic temperature controller | 4 sets ; Range: 0°~160° |

Infrared heating tube | 30pcs ; Power: 30kw |

Conveying device | Chain reciprocating |

Air cooling device | 1 set ; Power: 200w |

Free Member

Free Member 0

0 Chinese Supplier

Chinese Supplier